Fuel System EFI

#1

_2X044_

_2X044_

Posted 09 March 2009 - 02:50 PM

Got a few q's regarding my LH torana (sedan) fuel system.

I wish to run a LP pump into a surge tank followed by a HP pump into new fuel line/return line. My car also has to remain street legal as it is currently unregistered (to be registered) as such I would rather have all components mounted under the car rather than in the boot (If in the boot either the boot I will need to make the panel behind the rear seat a fire-wall ie. no holes).

Where have you guys got your LP pumps mounted (do they hang down like dog b____s)?

Has anyone managed to mount a surge tank and HP pump under there car?

Where have you run the new fuel lines? If you replaced the old; how have you attached the new lines/P clamps to the chassis rail? Is it legal/advisable to drill and tap?

Cheers,

#2

Posted 09 March 2009 - 03:54 PM

#3

Posted 09 March 2009 - 05:13 PM

#4

_the gts_

_the gts_

Posted 09 March 2009 - 06:53 PM

#5

Posted 09 March 2009 - 08:49 PM

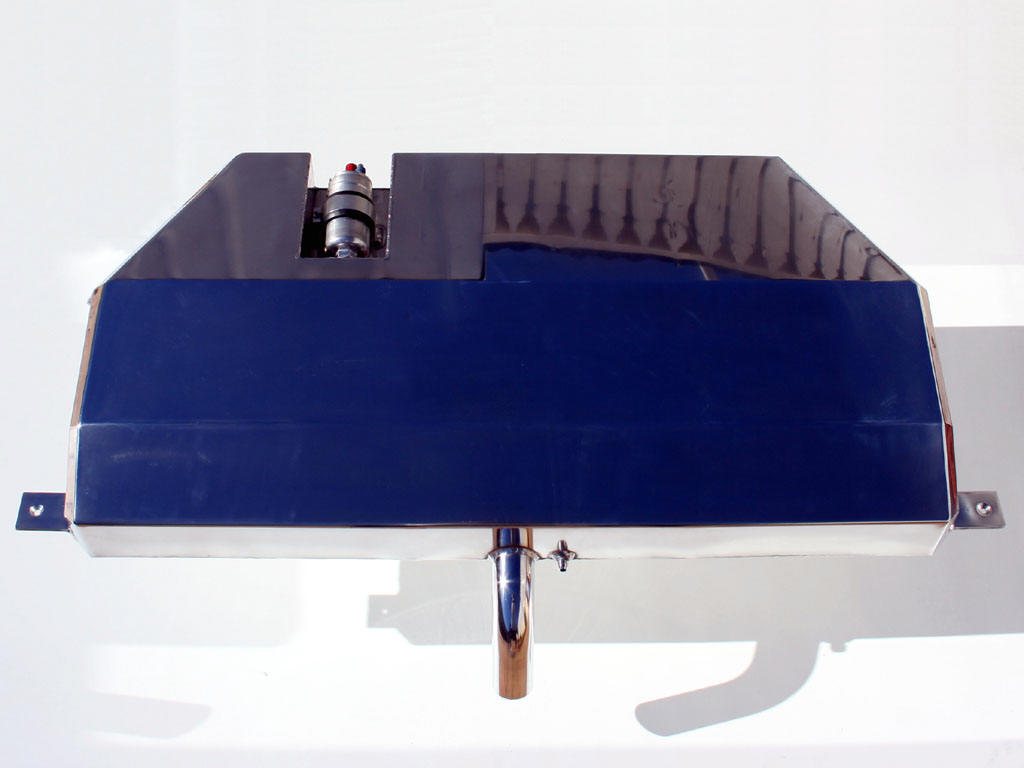

The dimensions are similar to the Brown Davis tank but 50 mm shorter, different angles at the front, different mounts and the flat spare wheel area. The tank is made from 3 mm sheet edge welded which is a totally different construction method to the Brown Davis tank. ( I think the Brown Davis construction method is better but not practical if you have to send sheet out for bending. )

The surge tank is 4.5 litres, the lift pump is a Goss GE034 and the EFI pump is a Bosch 044. The fuel filters are Aeromotive 100 micron for the lift and 10 micron for the EFI. The fuel level sender is VDO.

At each stage of fabrication, I have been taking the tank home to confirm measurements and clearances. I took this picture when I was checking the location of the pump, filter brackets, hose fittings and vents. The tank is back at Browns to be completed to the stage where it is ready for the top. Once that is done I will pickup the tank so I can test the surge tank return flow and internal construction. Then back to Browns to get the top tacked on, then back home to mark the mounting bracket positions then back to Browns to finish the tank. It has only taken three months so far

#6

_2X044_

_2X044_

Posted 10 March 2009 - 09:52 AM

I have had the recent thought of cutting out the spare wheel divot (bit rusted anyway) from the boot floor and replacing it with a flat or raised box section and using the new found space underneath to mount everything (with standard tank). Any thoughts?

ls2 are you using a "returnless" fuel supply system ie. pressure reg in the back of the car as common on some LS motors?

Interested in how you guys have done your replacement/additional fuel lines.

#7

_2X044_

_2X044_

Posted 10 March 2009 - 10:01 AM

Cheers

#8

Posted 10 March 2009 - 11:56 AM

Litre8 and A9X have a surge tank in the engine bay.

It would be worth checking if it is legal in your state to fit a surge tank in the engine bay. I am not particularly comfortable with the idea myself but it does have its benefits.

A forum member had a surge tank made that bolts to the boot floor with all the fuel fittings in the bottom of the tank with different length tubes. This allows you to have a surge tank in the boot with all the fuel lines external.

I plan to make my prototype fuel lines from 3/8" aluminium tube mounted using these clamps.. The lines will run down the drivers side on the outside of the chassis rail, under the guard to a bulkhead fitting in the splash panel. Up to the fuel rails then back to the regulator will be fitted to the splash panel. I plan attach the clamps using nutserts and mount a stone shield to the T-clamps where required. Once I have finished the fuel lines in aluminium tube I will remake them in stainless.

I expect to complete the prototype fuel lines in about five weeks.

Edited by ls2lxhatch, 10 March 2009 - 11:59 AM.

#9

Posted 10 March 2009 - 02:29 PM

We are about to bolt quad webers to the old girl and part of the job is to remove and replace both front tanks, fuel and oil catch. Have yet to finalise the actual plans for where the replacement is going.

Appreciate the links to the pipe clamps too, good stuff.

#10

Posted 10 March 2009 - 02:59 PM

#11

_2X044_

_2X044_

Posted 10 March 2009 - 03:04 PM

I have just ordered the clamps too. You should ask for a kick-back.

I don't entirely understand the location of your fuel lines. Will have a look under the car tonight to see if it all becomes suddenly clearer. I do have chassis stiffeners running down the outside of my chassis rails so it may be a bit tighter.

ls2lxhatch; Are your stone guards going to be folded aluminium or similar?

Does anyone foresee a problem with mounting the rails to the car floor on the inside of the drivers side chassis rail?

My apologies regarding the repeated questions.

#12

_the gts_

_the gts_

Posted 10 March 2009 - 11:20 PM

I like the way those pumps are set up mate they look good

#13

Posted 11 March 2009 - 01:29 AM

The fuel line guards will probably be made from 1 mm aluminium or mild steel sheet, possibly sprayed with proof coat.

The original fuel line runs on the inside of the drivers side chassis rail close to the exhaust and gearbox and then within an inch or two of the extractors. My fuel lines will follow the path of the original fuel lines from the tank up to the point where they cross over to the inside of the drivers chassis rail. At that point I will continue to run on the outside of the chassis rail to minimise exposure to heat from the exhaust, gearbox and extractors.

One problem with the return fuel system is that the fuel rails heat the surplus fuel passing through on its way back to the tank. Depending on the amount of fuel in the tank and the fuel system design it does not take long for the temperature in the fuel tank to rise considerably. Running the lines away from heat sources and in airflow will reduce the problem.

I also plan to mount an aluminium heat sink in the return line. The instructions show the heat sink mounted before the fuel rail but I think it will be more effective at keeping the tank cool fitted after the fuel rail. If fuel temperature is still a problem then I was considering fitting heat sinks to the bottom of the drop tank.

Edited by ls2lxhatch, 11 March 2009 - 01:34 AM.

#14

Posted 11 March 2009 - 08:38 AM

Had many a comment about the surge tank in it's location and with the added fire risk associated with racing and front end impact, i'll look to a change , maybe, as with the whole system.

#15

_2X044_

_2X044_

Posted 11 March 2009 - 04:00 PM

#16

_Terrible One_

_Terrible One_

Posted 12 March 2009 - 10:23 PM

I'll see if I can find a pic.

I'd probably advise to not put it in the boot, it'll smell bad and it's illegal.

#17

_2X044_

_2X044_

Posted 13 March 2009 - 11:20 AM

I'd be very interested in seeing your setup. I'm personally interested in the rectangular "L" shaped surge tanks that hold the fuel pump. ie. the top surge tank on this page http://www.aseturbo....el_systems.html.

Cheers

#18

Posted 13 March 2009 - 11:38 AM

I can see what you are trying to do putting the heat sink in the return line, but the intended purpose of these heat sinks is to cool the fuel as much as possible before the motor.

Cooler fuel is denser, so more bang available.

This is why some use ice tanks.

The pump actually heats the fuel during the pumping process. Its just physics.

A cooler in the return line isnt a bad idea, but one on the delivery side may be more beneficial.

#19

_82911_

_82911_

Posted 13 March 2009 - 12:33 PM

A neat in-tank solution. Single lift and dual pressure pumps.

Lift pump is fed from a split line that is routed to the rear corners of the cell.

As for the "heatsink" i think you are wasting your time. The fuel tank is the bigest heatsink you have.

Cheers Greg..

#20

Posted 13 March 2009 - 02:11 PM

#21

Posted 13 March 2009 - 02:22 PM

I can see what you are trying to do putting the heat sink in the return line, but the intended purpose of these heat sinks is to cool the fuel as much as possible before the motor.

The fuel tank is the bigest heatsink you have.

If you are building a car for the strip, then I agree that the optimal location for the heat sink is between the fuel pump and the fuel rails. I think this is more important for a carby than it is for EFI. I think the ECU is able to compensate for the higher fuel temperature by injecting a larger volume.

My car is intended as a daily driver so it will be stuck in traffic regularly. These are the issues I have been considering.

1. The heat sink will be most effective where the difference between air temperature and fuel temperature is the greatest.

2. The lift and EFI fuel pumps are cooled by the fuel, hot fuel can cause the fuel pumps to fail prematurely.

3. The temperature increase caused by the fuel pumps is trivial compared to the temperature increase caused by the fuel rails in a return line system at idle or low speeds.

4. I have seen fuel tanks on street cars that are too hot to touch after a long trip when the tank gets down below 1/4 full.

I was tempted to fit two heat sinks however space and cost is an issue. When the car is driven in traffic for half an hour or more I believe the heat sink in the return line will result in lower fuel temperatures overall and lower fuel temperatures in the fuel pumps. If there is any power loss due to higher fuel temperature at the fuel rails I doubt I will notice on the street.

Edited by ls2lxhatch, 13 March 2009 - 02:23 PM.

#22

_GMH355_

_GMH355_

Posted 14 March 2009 - 08:54 PM

If you are building a car for the strip, then I agree that the optimal location for the heat sink is between the fuel pump and the fuel rails. I think this is more important for a carby than it is for EFI. I think the ECU is able to compensate for the higher fuel temperature by injecting a larger volume.

My car is intended as a daily driver so it will be stuck in traffic regularly. These are the issues I have been considering.

1. The heat sink will be most effective where the difference between air temperature and fuel temperature is the greatest.

2. The lift and EFI fuel pumps are cooled by the fuel, hot fuel can cause the fuel pumps to fail prematurely.

3. The temperature increase caused by the fuel pumps is trivial compared to the temperature increase caused by the fuel rails in a return line system at idle or low speeds.

4. I have seen fuel tanks on street cars that are too hot to touch after a long trip when the tank gets down below 1/4 full.

I was tempted to fit two heat sinks however space and cost is an issue. When the car is driven in traffic for half an hour or more I believe the heat sink in the return line will result in lower fuel temperatures overall and lower fuel temperatures in the fuel pumps. If there is any power loss due to higher fuel temperature at the fuel rails I doubt I will notice on the street.

I tend to agree with ls2lxhatch. My fuel system was originally using a single bosch 044 pump, fed by a surge tank in the rear of the car. The return line from the fuel rail also feeds into the surge tank. After a long drive with only moderate throttle applications the surge tank was very warm to the touch. After fitting the second bosch 044 pump the surge tank was even hotter.

I was more concerned with the pumps overheating than the heat of the fuel in the rail. I wanted to take the heat out of the fuel (behaving like coolant) after it had circulated through the fuel rails. I fitted the following fuel cooler on the return fuel line before the surge tank.

By the way top work on your tank ls2lxhatch

0 user(s) are reading this topic

0 members, 0 guests, 0 anonymous users

View Garage

View Garage