T56 in hatch

#1

_project lx_

_project lx_

Posted 12 July 2016 - 08:47 PM

#2

_LS2 Hatch_

_LS2 Hatch_

Posted 12 July 2016 - 09:17 PM

Beside the point. If you have a tail shaft built to match the flange can't see why you can't.

#3

_project lx_

_project lx_

Posted 12 July 2016 - 09:26 PM

#4

Posted 12 July 2016 - 09:58 PM

Had one made start of the year

#5

Posted 13 July 2016 - 12:39 AM

The output shaft (in the transmission) is different between the flange and a slip yoke versions, but you can get a driveshaft made with an adapter and CV joint, which also saves some headaches with alignment angles...

001-3.jpg 134.7K

5 downloads

001-3.jpg 134.7K

5 downloads

003-2.jpg 133.75K

4 downloads

003-2.jpg 133.75K

4 downloads

You can also get a bolt-on tri flange to universal joint adapter from Sonnax...

TR6060 Tri Flange from Sonnax distributed by The Drive Shaft Shop TL35-ALFY-01_01.jpg 71.16K

3 downloads

TR6060 Tri Flange from Sonnax distributed by The Drive Shaft Shop TL35-ALFY-01_01.jpg 71.16K

3 downloads

...but either way you still need a slip joint built into the driveshaft.

#6

Posted 13 July 2016 - 06:07 AM

As long as its no bigger outside diameter than the cardan joint would be, with the extra length of the box you'll end up with it very close to the tunnel to get decent driveline angles

#7

Posted 13 July 2016 - 07:52 AM

Do you guys run single piece or two-piece tailshafts in cars with T56's?

#8

Posted 13 July 2016 - 09:36 AM

A two piece tailshaft would be unusual as it would be two very short sections. My tailshaft is only 39 inches (just over a meter), the T56 is a very long box and helps increase the drive line angel issue.

#9

_project lx_

_project lx_

Posted 19 July 2016 - 11:39 PM

#10

Posted 20 July 2016 - 05:02 PM

A two piece tailshaft would be unusual as it would be two very short sections. My tailshaft is only 39 inches (just over a meter), the T56 is a very long box and helps increase the drive line angel issue.

Cool, yeah I don't have any friends with two piece tailshafts in anything but big Chevs so I'm glad to hear that is the case.

Could you elaborate on the driveshaft angle issue?

#11

Posted 20 July 2016 - 07:24 PM

A Constant Velocity (CV) joint is just that, both sides of a CV run at a constant speed no matter what angle the joint is driving through.

A Cardan Joint (aka Universal Joint) doesn't. If the input speed is constant, the output will speed up and slow down as the joint turns, the average rotation is still the same (over 1 full turn) but this cycling motion gets more prominent as the angle increases, which in turn will increase driveline vibration. The drive angle through a uni joint should be kept to around 2-3° and you must always have some angle, never 0°

There are some videos on Youtube that explain this well...

For the above reason, you normally want an even number of uni joints in a drive shaft so one can balance another out, that way you get a constant speed in and out, but you would find that the driveshaft itself actually speeds up and slows down slightly during each revolution. That's why most two-piece driveshafts have a CV joint in the centre instead of a third uni joint.

Assuming the diff pinion angle stays the same, fitting a different transmission can change the driveshaft angles in a couple of ways:

If the gearbox is too big for the tunnel you might be tempted to let it sit lower at the rear crossmember so it doesn't hit the floor, this is bad because the output shaft and diff pinion will no longer be parallel.

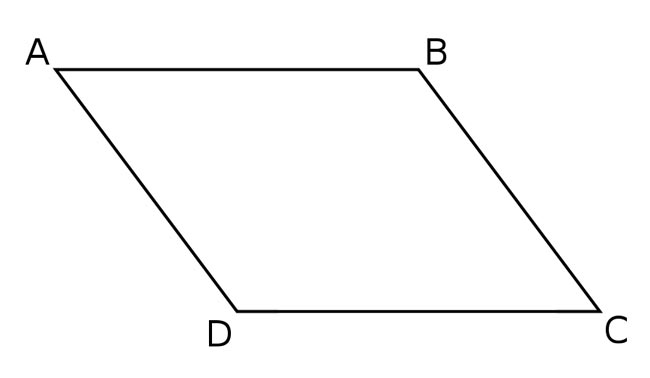

Or if the gearbox still sits at the correct angle but is much longer than standard, it's like moving one side of a parallelogram, the angle of the adjacent sides increase as too the angle of the driveshaft.

Let's say AB is the gearbox output shaft, and DC is the pinion shaft, both remain parallel but the further you push AB to the rear, the higher the angle of BC.

#12

_LS2 Hatch_

_LS2 Hatch_

Posted 20 July 2016 - 07:55 PM

What i don't understand is the idea of setting the diff 3 degrees negative for drag racing.

Setting it that far out must mean it lifts up a long way under acceleration. And they say that's good for 4 tenths over the quarter

Thanks for posting by the way, it's great and I couldn't find it again.

#13

_project lx_

_project lx_

Posted 20 July 2016 - 09:29 PM

#14

_project lx_

_project lx_

Posted 20 July 2016 - 09:33 PM

#15

Posted 20 July 2016 - 09:40 PM

Yep, as with any front wheel drive CV joint, the shaft is splined into the centre trunion, usually with a c-clip or similar to stop it pulling all the way out.

So yes, it has a slip joint built in to the design.

#16

_project lx_

_project lx_

Posted 20 July 2016 - 10:11 PM

#17

Posted 21 July 2016 - 07:51 AM

The drawback with CV joints is that they are heavier rotating mass. I'm also not sure how you'd go with a single CV and single cardan, because there would be nothing to cancel the harmonics of the cardan joint, it would need to be run at minimal angle. Possibly best suited to IRS with a fixed diff?

Yes, it can move a long way with big torque and slicks, and especially leaf springs. But never just pick numbers, you need to tailor the angles to your vehicle and intended usage (which means measuring!).What i don't understand is the idea of setting the diff 3 degrees negative for drag racing.

Setting it that far out must mean it lifts up a long way under acceleration.

Edited by 76lxhatch, 21 July 2016 - 07:52 AM.

#18

Posted 21 July 2016 - 10:56 AM

Go to the Mark Williams site, very good info. He built my shaft and I have 3 degrees on diff and engine, zero vibration.

http://www.markwilli...e9d8a-408659117

#21

Posted 21 July 2016 - 03:54 PM

Dunno? As strong as they are it only takes a decent stone chip to delaminate them. Also found this video interesting...

#22

Posted 21 July 2016 - 05:53 PM

Dunno? As strong as they are it only takes a decent stone chip to delaminate them. Also found this video interesting...

That vid was very cool!

#23

_LS2 Hatch_

_LS2 Hatch_

Posted 21 July 2016 - 07:11 PM

Go to the Mark Williams site, very good info. He built my shaft and I have 3 degrees on diff and engine, zero vibration.

http://www.markwilli...e9d8a-408659117

I have about three engine and diff also, and no vibration. But for the drags I have been told by reputable companies to be negative 3 diff regardless of engine/box angle. That would put me at a total of 6 degrees out. This does give a vibration over about 90-95km. Under hard acceleration it's ok, but I can't see how that helps. If I leave it what're it is normally and accelerate hard I don't get vibration, so why change it? I must be missing something?

76lxhatch how do you talor to your own car? How do you find out the correct adjustment?

Trial and error?

#24

Posted 21 July 2016 - 07:47 PM

Beyond that its a matter of accounting for the potential movement of the diff, start with a jack and seeing how much movement you can introduce via the bushings (people are telling you 3 degrees as an approximation, depends on suspension design, bushings, how much load it actually sees). Beyond that if you really need to find tune for specific activities you may need to get creative (camera under the car?) but that's probably taking things a bit far for most of us.

#25

Posted 21 July 2016 - 08:14 PM

An upside to them, they can dampen some harmonics, lower rotational mass.

Downside cost

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users

View Garage

View Garage