The structural oil pan is often misunderstood. What GM said is that the bolting the transmission to the oil pan increases the structural integrity of the powertrain. I guess it would also add a little to the strength of the block however if you were serious about strengthening the block then your would probably fit a steel girdle on the mains not a cast aluminium oil pan. The deeper skirt on the LS block with cross bolt mains already increases the strength of the bottom end compared to a SBC block.

This quote is discussing the V6 oil pan but I read a similar quote for the LS1 although I can't find it at the momement.

A cast aluminum oil pan is stiffened to improve powertrain rigidity and reduce vehicle vibration.

http://gmauthority.c...gm-engines/lfx/

It is also mentioned here.

http://www.hotrodlan...nstallation.htm

The alignment of the structural oil pan is critical. The rear bolt hole locations of the oil pan provide mounting points for the transmission housing. To ensure the rigidity of the powertrain and correct transmission alignment, it is important that the rear of the block and the rear of the oil pan are flush

The older transmissions are only bolted to the block so the bolts cover a little over 180°. The LS transmissions are bolted to the block and the oil pan giving 360°. The drivetrain is less likely to flex with 360° bolts than it is with 180° bolts. If you are not running a LS transmission then it doesn't matter what pan you use. If you are running a LS transmission with a aftermarket pan then you are no worse off than someone running a SBC. You could run a brace from the block to the bottom transmission holes if you wanted additional strength.

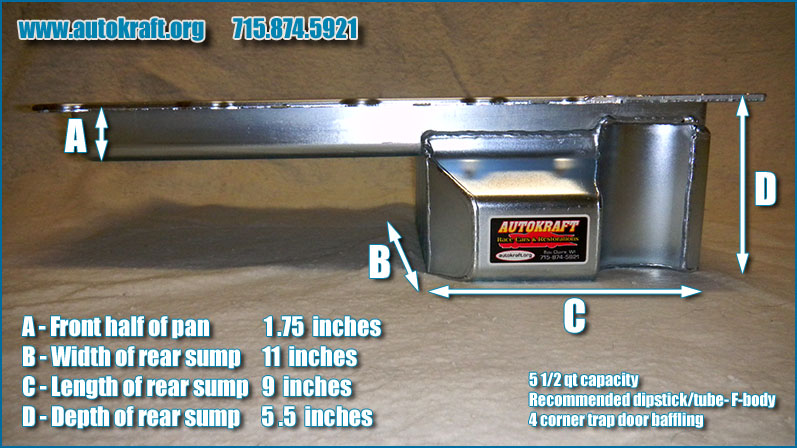

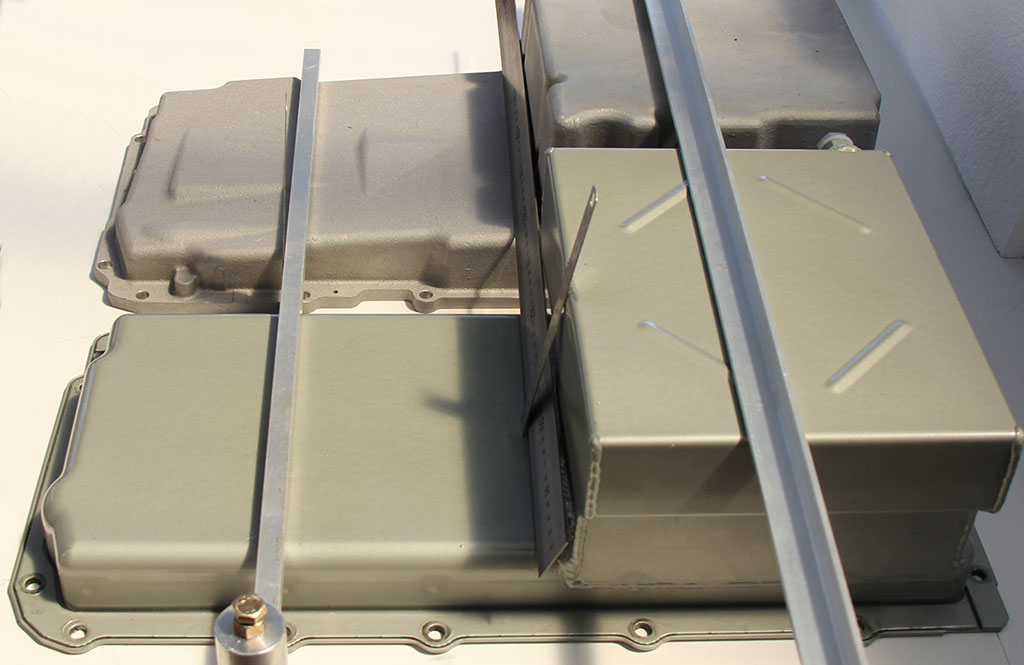

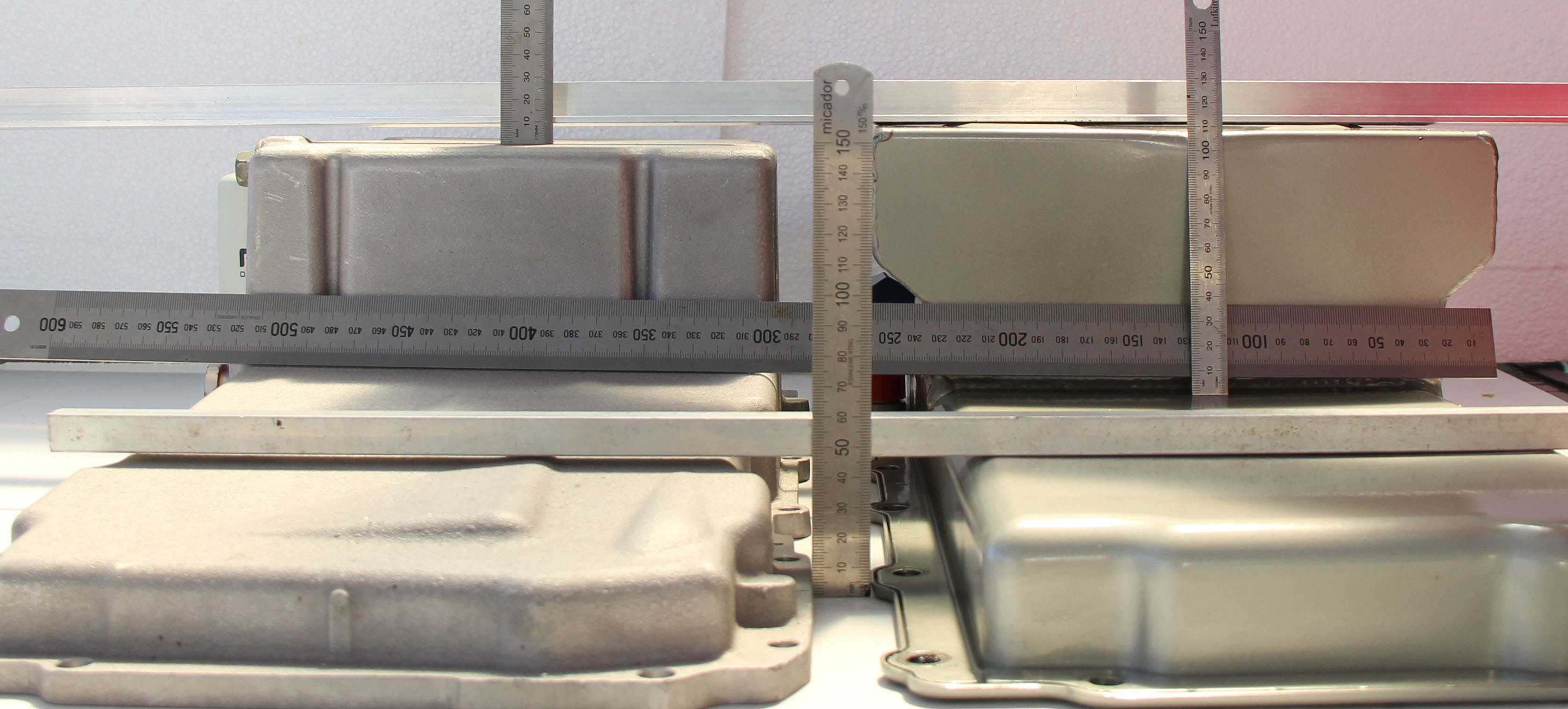

There is baffling in the Mast oil pan but no trap doors. From memory the baffling is similar to the Camaro pan. I can take a picture tonight. I plan to run an Accusump as insurance against oil surge and to prime the engine before starting.

Edited by ls2lxhatch, 13 February 2014 - 03:19 PM.